Ana yin kebul na sadarwa mai yawan mita da ƙarancin asara gabaɗaya daga polyethylene mai kumfa ko polypropylene mai kumfa azaman kayan rufewa, wayoyi biyu na tsakiya masu rufewa da waya ta ƙasa (kasuwar yanzu tana da masana'antun da ke amfani da ƙasa biyu) a cikin injin na lanƙwasa, suna naɗe foil ɗin aluminum da tef ɗin polyester na roba a kusa da wayar tsakiya mai rufewa da waya ta ƙasa, ƙirar tsarin rufewa da sarrafa tsari, tsarin layin watsawa mai sauri, buƙatun aikin lantarki da ka'idar watsawa.

Bukatar jagora

Ga SAS, wanda kuma layin watsawa ne mai yawan mita, daidaiton tsarin kowane sashi muhimmin abu ne wajen tantance mitar watsawa na kebul. Saboda haka, a matsayin mai jagorantar layin watsawa mai yawan mita, saman yana da zagaye kuma santsi, kuma tsarin tsarin layin ciki yana da daidaito kuma mai karko don tabbatar da daidaiton halayen lantarki a cikin alkiblar tsayi; Mai jagoran ya kamata kuma yana da ƙarancin juriyar DC; A lokaci guda ya kamata a guji saboda waya, kayan aiki ko wasu na'urori da lanƙwasawa na ciki ko lanƙwasawa mara lokaci, nakasa da lalacewa, da sauransu ke haifarwa, a cikin layin watsawa mai yawan mita, juriyar mai jagoran shine babban abin da ke haifar da raguwar kebul (ma'aunin mita mai yawa na asali sashi na 01- sigogin rage gudu), akwai hanyoyi guda biyu don rage juriyar mai jagoran: ƙara diamita mai jagoran, zaɓar kayan mai jagorar ƙarancin juriya. Bayan diamita mai jagorar ya ƙaru, don biyan buƙatun juriyar halayyar, diamita na waje na rufin da diamita na waje na samfurin da aka gama suna ƙaruwa daidai gwargwado, wanda ke haifar da ƙaruwar farashi da sarrafawa mara dacewa. A ka'ida, ta amfani da na'urar sarrafa azurfa, diamita na waje na samfurin da aka gama zai ragu, kuma aikin zai inganta sosai, amma saboda farashin azurfa ya fi farashin tagulla yawa, farashin ya yi yawa don samar da taro, don la'akari da farashi da ƙarancin juriya, muna amfani da tasirin fata don tsara na'urar sarrafa kebul. A halin yanzu, amfani da na'urorin sarrafa tagulla da aka yi da gwangwani don SAS 6G na iya biyan aikin lantarki, yayin da SAS 12G da 24G suka fara amfani da na'urorin sarrafa azurfa.

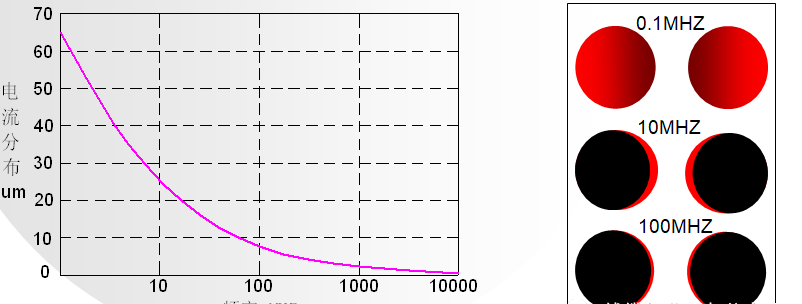

Idan akwai wutar lantarki mai canzawa ko kuma wutar lantarki mai canzawa a cikin mai gudanarwa, rarrabawar wutar lantarki a cikin mai gudanarwa ba ta daidaita ba. Yayin da nisan da ke tsakanin saman mai gudanarwa ke ƙaruwa a hankali, yawan wutar lantarki a cikin mai gudanarwa yana raguwa sosai, wato, wutar lantarki a cikin mai gudanarwa zai mai da hankali kan saman mai gudanarwa. Daga saman mai juyawa zuwa ga alkiblar wutar lantarki, ƙarfin wutar lantarki na tsakiyar ɓangaren mai gudanarwa a zahiri sifili ne, wato, kusan babu kwararar wutar lantarki, kuma ɓangaren da ke gefen mai gudanarwa ne kawai zai sami ƙananan wutar lantarki. A taƙaice, wutar lantarki tana tarawa a cikin ɓangaren "fata" na mai gudanarwa, don haka ana kiranta tasirin fata. Dalilin wannan tasirin shine canjin filin lantarki yana samar da filin lantarki mai canzawa a cikin mai gudanarwa, wanda wutar lantarki ta asali ke daidaita shi. Tasirin fata yana sa juriyar mai jagora ta ƙaru tare da ƙaruwar mitar wutar lantarki mai canzawa, kuma yana haifar da raguwar ingancin wutar lantarki ta waya, yana cinye albarkatun ƙarfe, amma a cikin ƙirar kebul na sadarwa mai yawan mita, ana iya amfani da wannan ƙa'ida don rage yawan amfani da ƙarfe ta hanyar amfani da faranti na azurfa a saman ƙasa bisa ga tsammanin biyan buƙatun aiki iri ɗaya, ta haka rage farashi.

Bukatar rufi

Kamar yadda ake buƙata daga mai gudanarwa, ya kamata ma'aunin rufewa ya zama iri ɗaya, kuma domin samun ƙarancin dielectric constant s da dielectric loss ƙimar tangent na kusurwa, kebul na SAS gabaɗaya suna amfani da kumfa mai hana kumfa. Lokacin da matakin kumfa ya fi 45%, kumfa mai hana kumfa yana da wahalar cimmawa, kuma matakin kumfa ba shi da ƙarfi, don haka kebul ɗin da ke sama da 12G dole ne ya yi amfani da kumfa mai hana kumfa. Kamar yadda aka nuna a cikin hoton da ke ƙasa, lokacin da matakin kumfa ya fi 45%, ɓangaren kumfa mai hana kumfa da kumfa mai hana ...

kumfa ta zahiri Sinadaran sinadaraikumfa

Lokacin Saƙo: Afrilu-20-2024