SAS (Serial Attached SCSI) sabon ƙarni ne na fasahar SCSI. Daidai ne da mashahurin Serial ATA (SATA) hard disks. Yana amfani da fasahar Serial don cimma mafi girman saurin watsawa da haɓaka sararin ciki ta hanyar rage layin haɗin gwiwa. Domin danda waya, a halin yanzu yafi daga lantarki yi don rarrabe, raba zuwa 6G da 12G, SAS4.0 24G, amma na al'ada samar tsari ne m guda, a yau mun zo raba, Mini SAS danda waya gabatarwar da samar da tsari kula da sigogi. Domin SAS babban mitar layin, impedance, attenuation, madauki asarar, crosswish da sauran watsa Manuniya ne mafi muhimmanci, da kuma SAS high mita aiki mita ne kullum 2.5GHz ko fiye a karkashin high mita, bari mu dubi yadda za a samar da wani m high gudun line SAS.

Ma'anar tsarin kebul na SAS

Low hasara a high mita sadarwa na USB yawanci sanya na kumfa polyethylene ko kumfa polypropylene a matsayin rufi kayan, biyu insulated madugu tare da ƙasa waya (kasuwar kuma yana da manufacturer AMFANIN biyu hanya biyu) a cikin shata jiragen, waje da makaran shugaba da ƙasa waya winding da aluminum tsare da lamination polyester bel, rufi tsari zane da kuma aiwatar da tsarin da lantarki da kuma canja wurin da bukatun, da tsarin da kuma canja wurin tsarin.

Abubuwan da ake buƙata don masu gudanarwa

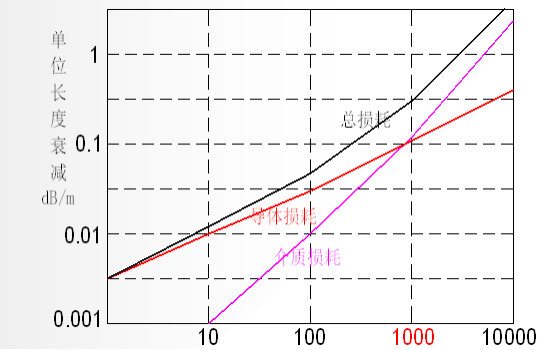

Don SAS, wanda kuma babban layin watsawa ne, daidaitaccen tsarin kowane bangare shine maɓalli don tantance mitar watsa na USB. Sabili da haka, a matsayin mai gudanar da layin watsawa mai girma, saman yana zagaye da santsi, kuma tsarin tsararru na ciki ya kasance daidai da kwanciyar hankali, don tabbatar da daidaiton aikin lantarki a cikin tsawon shugabanci; Hakanan ya kamata mai gudanarwa ya kasance yana da ƙarancin juriya na DC; A lokaci guda ya kamata a kauce masa saboda wayoyi, kayan aiki, ko wasu na'ura na ciki madugu lankwasawa lokaci-lokaci ko aperiodic lankwasawa, nakasawa da kuma lalacewa, da dai sauransu, a cikin high mita watsa Lines, madugu juriya ne lalacewa ta hanyar na USB attenuation (high mita sigogi tushe takarda 01 - attenuation) na manyan dalilai, akwai hanyoyi guda biyu don rage madugu juriya: ƙara da madugu diamita, zabi da low conductivity juriya. Lokacin da diamita na jagora ya karu, don biyan bukatun halayen halayen halayen, ya kamata a ƙara diamita na waje na rufi da ƙãre samfurin daidai da haka, yana haifar da karuwar farashi da aiki mara kyau. Yawanci amfani low resistivity na conductive kayan ga azurfa, a ka'idar, AMFANI da azurfa madugu, ƙãre samfurin diamita zai rage, za su sami babban yi, amma saboda farashin azurfa ne nisa mafi girma fiye da farashin jan karfe, da kudin ma high, ba zai iya samar, domin su iya yin la'akari da farashin da low resistivity, mu yi amfani da fata sakamako, don zana na USB madugu, A halin yanzu, SASnned yi amfani da wutar lantarki ko jan karfe 6G. 12G da 24G sun fara amfani da madugu-plated azurfa.

Lokacin da aka sami madauwari na halin yanzu ko musanyawan filin lantarki a cikin madugu, lamarin rashin daidaituwa na rarrabawar yanzu zai faru a cikin madubin. Yayin da nisa daga saman madubin ya karu, yawan halin yanzu a cikin madubi yana raguwa sosai, wato, halin yanzu a cikin madubi yana maida hankali kan saman madubin. Daga ra'ayi na sashin giciye daidai gwargwado zuwa jagorar halin yanzu, ƙarfin halin yanzu a tsakiyar ɓangaren mai gudanarwa shine m sifili, wato, kusan babu kwararar yanzu, kawai a cikin ɓangaren gefen madubin zai sami ƙananan kwarara. A cikin sauƙi, halin yanzu yana maida hankali ne a cikin ɓangaren "fata" na madugu, don haka ana kiransa tasirin fata kuma tasirin yana faruwa ne ta hanyar canza filin lantarki wanda ke haifar da filin lantarki na vortex a cikin madubi, wanda ke soke ainihin halin yanzu. Skin sakamako sa juriya na madugu ya karu da mita na alternating halin yanzu karuwa, da kuma sakamakon a cikin rage halin yanzu yadda ya dace da waya watsa, amfani da karfe albarkatun, amma a cikin zane na high mita sadarwa na USB, amma zai iya yi amfani da wannan ka'ida, tare da hanyar plating azurfa a kan surface don saduwa da wannan aikin da bukatun karkashin jigo na rage karfe amfani, don haka rage farashin.

Bukatun rufi

Matsakaicin suturar dole ne ya zama iri ɗaya, wanda yayi daidai da na jagorar. Don samun ƙananan dielectric akai-akai S da tangent na dielectric asarar Angle, SAS igiyoyi yawanci ana kebe su ta hanyar PP ko FEP, kuma wasu igiyoyin SAS kuma ana rufe su da kumfa. Lokacin da digirin kumfa ya fi 45%, kumfa sinadarai yana da wuya a cimma, kuma digirin kumfa bai tsaya ba, don haka kebul a kan 12G dole ne ya ɗauki kumfa ta jiki.

Babban aikin endodermis kumfa na jiki shine ƙara haɓaka tsakanin mai gudanarwa da rufi. Dole ne a ba da garantin wani mannewa tsakanin rufin rufin da mai gudanarwa; in ba haka ba, za a samar da ratar iska tsakanin insulating Layer da madugu, sakamakon canje-canje a cikin dielectric akai £ da tangent darajar dielectric asarar Angle.

Polyethylene rufi kayan da aka extruded zuwa hanci ta dunƙule, kuma ba zato ba tsammani fallasa zuwa yanayi matsa lamba a fita daga hanci, kafa ramuka da kuma haɗa kumfa. A sakamakon haka, iskar gas yana fitowa a cikin ratar da ke tsakanin madubi da budewar mutu, yana samar da dogon rami mai kumfa tare da saman madubin. Don magance matsalolin biyu na sama, wajibi ne don extrude kumfa Layer a lokaci guda ... The bakin ciki fata ne squeezed a cikin ciki Layer don hana iskar gas daga ana saki tare da surface na madugu, da kuma ciki Layer iya rufe kumfa don tabbatar da uniform kwanciyar hankali na watsa matsakaici, don rage attenuation da jinkiri na na USB, da kuma tabbatar da wani barga halayyar impedance a cikin dukan layin. Don zaɓin endodermis, dole ne ya dace da buƙatun bangon bango na bakin ciki a ƙarƙashin yanayin samar da sauri, wato, kayan dole ne su sami kyawawan kaddarorin haɓaka. LLDPE shine mafi kyawun zaɓi don biyan wannan buƙatun.

Bukatun kayan aiki

Insulated core waya shine tushen samar da kebul, kuma ingancin core waya yana da tasiri mai mahimmanci akan tsari na gaba. A cikin aiwatar da ɗaukar waya mai mahimmanci, ana buƙatar kayan aikin samarwa don samun kulawa ta kan layi da aikin sarrafawa don tabbatar da daidaito da kwanciyar hankali na waya mai mahimmanci, da sigogin tsarin sarrafawa, gami da diamita na waya mai mahimmanci, ƙarfin ruwa a cikin ruwa, haɓakawa, da dai sauransu.

Kafin bambance-bambancen wayoyi, ya zama dole don dumama bel ɗin polyester mai ɗaure kai don narkewa da haɗa manne mai zafi mai zafi akan bel ɗin polyester mai ɗaure kai. Sashin narke mai zafi yana ɗaukar na'urar dumama zafin wutar lantarki mai iya sarrafawa, wanda zai iya daidaita zafin dumama daidai daidai da ainihin buƙatun. Akwai hanyoyin shigarwa a tsaye da a kwance na babban preheater. A tsaye preheater iya ajiye sarari, amma winding waya bukatar ya wuce ta mahara regulating ƙafafun tare da manyan kusurwoyi don shigar da preheater, wanda yake da sauki canza dangi matsayi na insulating core waya da nannade bel, sakamakon da ya haifar da koma baya na lantarki yi na high-mita watsa layin. Sabanin haka, preheater a kwance yana cikin layi ɗaya tare da nau'in layi na nannade, kafin shigar da preheater, layin layin kawai yana wucewa ta wasu ƙafafu masu daidaitawa tare da rawar daidaitawar ƙasa, saƙa layin layi ba ya canza Angle lokacin da yake wucewa ta hanyar dabaran daidaitawa, yana tabbatar da kwanciyar hankali na matsayi na sakawa na bel ɗin insulating da waya. Rashin lahani na na'urar da ke kwance a kwance shine yana ɗaukar sarari da yawa kuma layin samarwa ya fi tsayi fiye da injin iska tare da preheater a tsaye.

Lokacin aikawa: Agusta-16-2022